Maintenance

DENTAL CHAIRS

Cleaning

Use the least amount of chemicals possible and only those recommended by the manufacturer and only wipe with damp cloth onto chair never spray.

On surfaces touched often use a barrier rap and remove at end of day.

On surfaces not touched by bloody hands a diluted water and detergent solution.

Upholstery should be buffed once a month with a revive product recommended by the manufacture.

On headrests a cover should be used to protect from chemicals like hairsprays.

Suction

Clean the amalgam filter at the end of the day before suction cleaning. If there has been any chemicals (ie: tooth whitening) or a very bloody procedure performed, flush with fresh water dipping in and out of a 500ml jug to ensure the internal pipes are clean.

The procedure should also be performed at the end of the day before the daily suction cleaning. The reason for this is the less blood in the pipes the less the suction cleaning solution reacts to and therefore less chance of blockages in you main pipe.

Operating Light

Clean the light cover once a month with a lint free cloth if needed the reflector as gently as possible with no chemicals.

If any blood has been spilled on the reflector only use isopropyl alcohol.

If the lamp is touched with finger tips clean with alcohol before turning on as lamp may explode.

If the unit has fans use syringe air to blow out vents to prevent overheating.

Doctor's Tray

Empty oil trap once a month.

Remove all couplings once a month turn water valves up to full and flush lines.

If you have a clean water system and don't use a patient safe bio retardent then use an algae killer like miltons solution in your bottle and flush all lines and syringes for 20 seconds each, then leave five minutes before repeating with fresh water.

Only FILTERED water (NOT distilled) should be used in clean water systems. All couplings should have a smear of O'ring lubricant or vaseline before refitting.

Air motors should be oiled through the smaller of the two large holes before refitting.

HANDPIECES

If you change handpiece types then you may need to get you pressures reset or you will be replacing your turbines in six months.

All high and low speeds MUST be oiled before they are autoclaved. Remember high-speeds run at 300-350,000 rpm (Would you run your car like that without oil ?).

You should only use the oil recommended by the manufacturer and ensure the oil adaptor is in good condition.

If you have had to use a lot of oil to clean high or low speed you may need to refit to coupling and run for a few seconds or leave upright to flush out excess oil.

Only a half second spray is usually necessary but if any dirt comes out you must keep spraying until the oil is clean or the dirt will cause wear to your turbine.

If a low speed pressurizes and blows off adaptor and no oil comes out you may need to break up contra angle and flush seperatly.

AUTOCLAVES

DAILY

Clean the door seal and the seal facia with a damp cloth daily.

If there are any ridges they should not be cleaned with anything more abrasive then a scotchbrite pad.

Check all trays and the chamber or cassette tray is similarly clean. Do not overfill reservoir.

MONTHLY

Remove seal and clean with soft brush clean seal housing of debris or rust.

Use high volume to suck out reservoir debris and refill.

Backup cycle files to computer.

6 MONTH

Replace biofilter or as directed by Autoclave manufacturer

Clean all air vents, dust filters and vacuum radiator fins. Ensure adequate space at rear of Autoclave for optimal performance.

ANNUAL

By law (refer: AS/NZS 4815/4817) you are required to have your Autoclave calibration checked by Lab Certified test equipment annually.

At this time it is recommended to get your unit serviced so it is ready for your annual P.Q (Performance Qualification).

Hints

PLANT ROOM

Compressor

Check the power is on use something that makes noise to ensure power point works. Check the airline is plugged in to the compressor and there is no kinks in the line and any isolator is on. If the power is on but the compressor doesn't start check the pressure switch is on the 'I' position or if it has a control box that the on switch is pressed. If it still doesn't go check the motor overload button which should be on the motor or the control box.

If the compressor goes but doesn't have enough pressure or runs on check the drain valve is shut. The compressor has two gauges one is off the tank and the motor should start when it reaches 80 psi [5.5bar] and stop at 120 psi [8.5bar] approximately. The other gauge is on the regulator where the airline goes in and should read 80 psi [5.5bar].

Suction

Check the power point works if it is a dryline check motor works by plugging directly in to power point if it doesn't go check overload isn't tripped. Check controller is going by lifting suction or shorting control wires and listen for relay click if it doesn't work you can plug power directly into power till technician arrives.

If its a wet line check the unit is plugged in and the main switch is on and the power on light is lit and the filter is clear. Short the control wire and check suction goes if it doesn't call technician. If it goes but no suction at high volume you may have a faulty suction isolator in the chair.

DENTAL CHAIR

No Power

Check the main switch on the wall is on. If you have no power to the chair check that the RCD is on and that the power available and power on light are both lit. If they aren't, reset circuit breaker and RCD. Check the master switch on the dental chair is on. This is usually on the doctors tray and will have a O & I switch to the I position (note most switches use air so make sure the compressor is on). If the operating light works but the chair doesn't check the chair main switch is on and lit.

Chair Not Moving

Check the chair power is on and lit. If the chair only moves up check the safety switches there is usually one on the backrest one on the seat upholstery and one under the cantilever part of the seat or on the base itself. If the chair is connected to a spittoon check the bowl and the suction arm.

No Air

Check the delivery unit master switch is on. Check the syringe air. If there is no air check the compressor.

No Water

Check the delivery unit master switch is on. Check the spittoon and cupfill work. If they don't, check the backflow preventer or master water isolator is on. If they work, but not the syringe, does the unit use a clean water system? If it does ensure the bottle is full and switched on. When you switch it on make sure you can hear it fill with air and if it has a gauge that it reads 40 psi [2.2 bar].

If the syringe works but not the highspeed, check the water spray switch on the foot control or doctors tray is on. Remove the coupling from the tubing if water comes out then the coupling is blocked or water control ring is off. If water does come out but is weak you may have algae massage the tubing with the water valve on full while pumping the foot control.

Suction Weak

First check that your amalgam filter is clean. A good indicator of suction strength is to fill a cup to the top and drop you high volume in while counting one, one thousand two, one thousand etc. Good suction should empty the cup by two if it takes longer than three check your main suction filter. If your saliva ejector is weak it is most likely amalgam powder settled in the lowest point of the tubing massage it while its going to clear it. If water dribbles out when the isolater is lifted then the tubing may be partially collapsed.

If all else checks out OK and suction is still weak check suction motor filter in plant room.

Gallery

Click on the images below to see a category of photo's

(Unauthorised use or reproduction of any images on this website is prohibited)

HISTORY

Hi. My name is David Priest. I have worked in the dental industry for over 20 years . I started my career as a trainee air conditioning engineer, but found the cold didn't agree with me. So I changed to plastic die setting until loosing a finger, and deciding I wanted to keep the rest of them, I went back to my first love and became an electrician specializing in commercial and industrial.

After many years crawling under and over things, I decided I needed a change and became a sterilizer engineer, building / installing / servicing and validating hospital and research lab autoclaves as well as doing R&D for new products in our field. After one to many nights working through to the morning getting CSSD autoclaves ready for the next mornings theatre list, I decided a change was needed, so I took on a job with R.A Jenks under Chris Pexton.

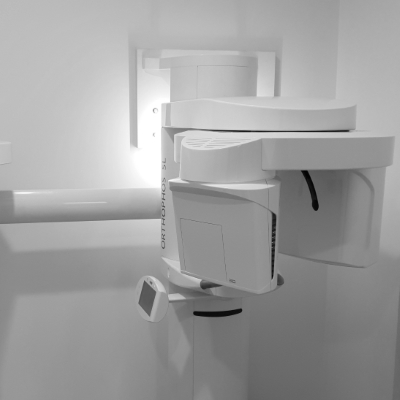

Back then cow pumps, vacuum cleaners and belt driven oil compressors weren't uncommon, but wet line pumps were. With x-ray dip tanks with fish tank heaters giving way to phosphor plates and digital sensors, oil compressors to silenced oil-less and dryer, and from chairs with foot pedals to raise them, to chairs with internet connection so they can be fault diagnosed online, how things have changed!

With all these changes over the years the basics still remain the same. A surgery still needs a reliable and well maintained plant room and an efficient and well laid out surgery and sterilization area, future proofed to meet the needs of your business in the most economical way.

My whole career in my different trades has been focused on repair and servicing to maintain a reliable system. From cleaning air conditioning towers when I left school, to being responsible for programmed maintenance of multiple major hospital and research labs in the North Island, has helped me to know what is needed to keep you running smoothly and cost effectively so you can focus on growing your business.

I hope you will consider me an asset to your business now and for many years to come.

David Priest

Director